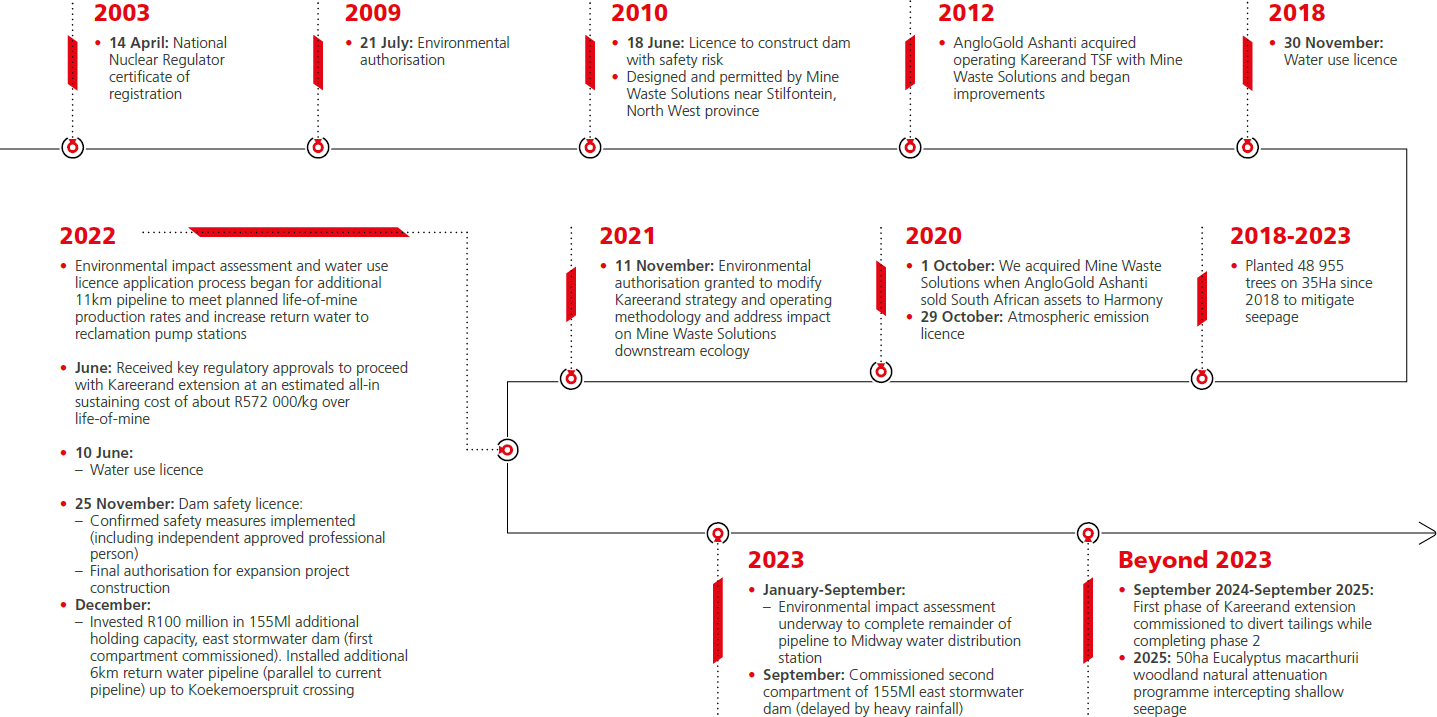

Kareerand: A robust design and impeccable operational management

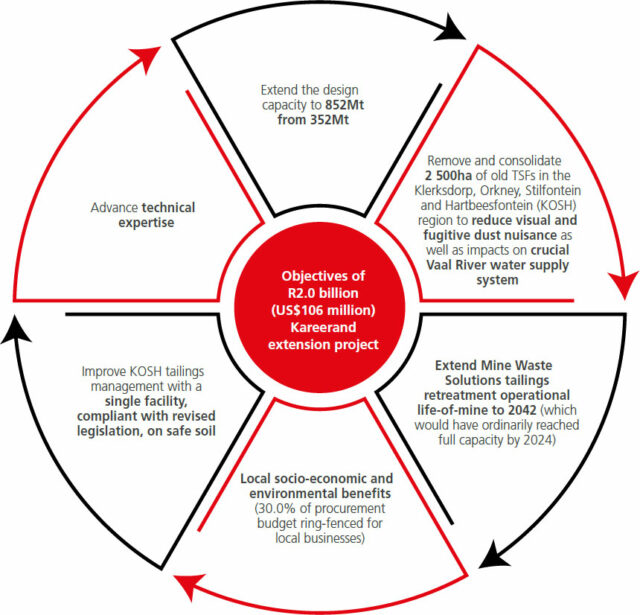

As part of our commitment to our responsible stewardship strategic pillar, our tailings management measures at Kareerand limit Harmony’s negative environmental impacts, particularly on the nearby Vaal River, which is a crucial water source for South Africa and neighbouring communities.

Kareerand is necessary to one of our key circular economic initiatives in our organisation. We are a business that retreats our tailings dams to harvest gold from what would otherwise have been just a mineral waste dump. Harmony has the largest gold reclamation business globally. This initiative allows us to process gold in a safe and environmentally responsible and economical manner. It has the added advantage of being less energy intensive than conventional mining. It also provides an opportunity to process mine waste with modern techniques that ensures we deliver a less toxic, more stable footprint, that frees up large areas of land for productive use.

The first phase will include the construction of additional return water and stormwater handling facilities to enable closure of most old tailings dams on unstable dolomitic soil in the KOSH region. To this end, an additional 6km return water pipeline from Kareerand to the Midway distribution station has been completed. This additional pipeline increases the rate at which Mine Waste Solutions can return water to tailings reclamation operations and the processing plant. Return water is recycled to relieve pressure on stressed potable water sources.

Kareerand is of strategic importance to Harmony. It fulfils the criteria of a circular economy for gold, it has a lower energy intensity profile when compared to other operations, and it assists in consolidating tailings onto one footprint, rather than multiple footprints across various areas.

Extensive water management measures, primarily to ensure dam integrity by restricting water pooling on top of the facility, include:

- Maximum return water reuse

- Optimal water drainage and removal

- Berm walls and paddocks on side slopes to trap silt

- A geomembrane liner to avoid groundwater and surface impacts

- The phyto-evaporative transpiration cover to maximise basal coverage

Harmony also manages dust emanating from the TSF by monitoring results at sampling points and implementing mitigation measures where necessary.

Kareerand is on stable geology certified by, among other regulations, the South African National Standard (SANS) for mine residue, SANS 1200 for the Standardisation Specification for Civil Engineering Construction and the Global Industry Standard on Tailings Management. We also regularly monitor and report the performance of the TSF to authorities, and continue engaging with key stakeholders on progress.

Over more than 12 years, the Kareerand TSF has been managed with the health and safety of people and the environment in mind. We continue to proactively mitigate potentially harmful impacts with sustainable innovative measures.